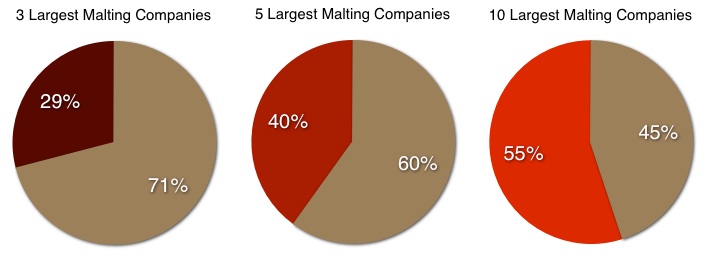

My investigation into the global malt supply chain started with an overall profile of the industry. I looked at the global malting companies that supply the bulk of the world’s malt, and I examined the smaller companies that supply malt for the craft brewing industry.

My investigation into the global malt supply chain started with an overall profile of the industry. I looked at the global malting companies that supply the bulk of the world’s malt, and I examined the smaller companies that supply malt for the craft brewing industry.

Now I want to look at malthouses that are the opposite of the the huge global corporations, companies that are very small and very local. To that end, I recently spoke with Andrea Stanley from Valley Malt, a craft malthouse in Massachusetts. She was kind enough to share some of her thoughts about the malting industry and Valley Malt’s place in it. Continue reading